Council Tool has been crafting high-quality tools and axes since the late 1800s, and the story of this American company is full of passion, innovation, and resilience. Let’s dive into the rich history and discover how this iconic company has thrived through the decades.

Table of Contents

Council Tool has been crafting high-quality tools since the late 1800s, and the story of this American company is full of passion, innovation, and resilience. Let’s dive into the rich history and discover how this iconic company has thrived through the decades.

Early Years and Expansion

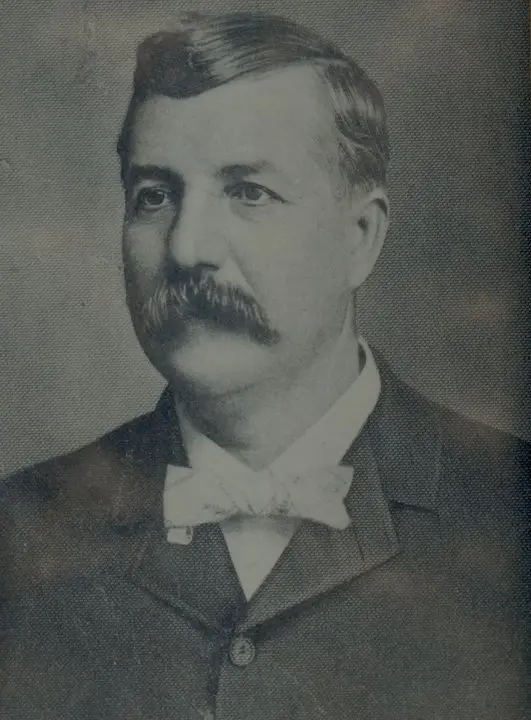

John Pickett Council was born in 1855 at Council Station in North Carolina. He was the third son and eighth child in a family of fifteen. Known for his energy and creativity, J.P. wore many hats throughout his youth. He farmed, ran a general store, and produced naval stores. Dissatisfied with the tools for naval stores, he began making his own, tweaking designs and eventually crafting better versions. His tools caught on, and seeing a good opportunity, he decided to focus on tool-making and incorporating the company in 1886.

J.P.’s first workshop was a simple log building with one forge. He heated steel in a coke-fired furnace and used hand-operated bellows. Unfortunately, a fire destroyed this building in the early 1890s. Undeterred, he built a larger facility with six forges and a steam boiler to power bellows and grinding wheels.

The naval stores industry during this period was thriving, primarily due to the vast longleaf pine forests in southeastern North Carolina. Workers tapped the sap from these pines through a method called chipping, which involved removing bark and making cuts to collect the flowing resin in metal cups. This resin was then transported to distilleries to produce rosin and spirits of turpentine, which were in high demand for shipbuilding, soaps, paints, and medicines. This created a booming market that stretched from southeastern North Carolina down through Florida and across the southern states to Texas.

With limited road infrastructure and no motor freight lines, railroads were crucial for transporting goods. Council Tool relied on two main rail lines: the Seaboard Air Line Railway to Wilmington and the Atlantic Coast Line from Wilmington to Florence, extending further south. Goods crossed the Cape Fear River at Wilmington. However, a unique and somewhat frustrating arrangement existed between the two rail carriers. Despite transferring the freight before the bridge, Mr. Council was charged transfer fees by both carriers.

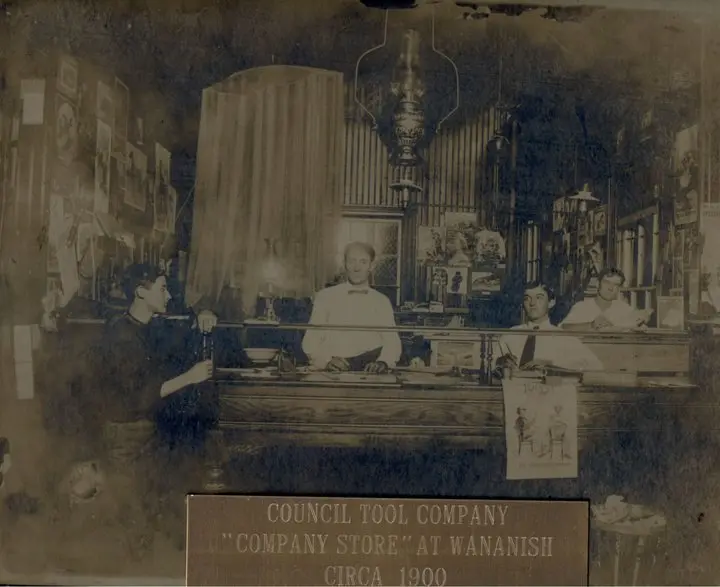

To get around this unnecessary expense and streamline his operations, Mr. Council came up with a plan. Seeing the strategic importance of Lake Waccamaw—about ten miles from Council along the Atlantic Coast Line—he realized he could cut costs and boost efficiency. Being an avid hunter and fisherman, he bought a large piece of land near Lake Waccamaw around 1902. He built a big house and paved a road connecting it directly to the factory, which he set up a few hundred feet south of the rail line. He also developed the area around the factory by setting up a general store similar to the one he had in Bladen County.

By the 1920s, Council Tool continued as a blacksmith shop. The day-to-day operations at Council Tool painted a picture of hands-on craftsmanship and a close-knit community. To support their employees, the company constructed between fourteen and eighteen houses. Initially, these homes were rent-free, later shifting to nominal rental charges, and eventually, they were sold to the workers. Many of these homes remain in the families of the original employees.

In July of 1913, disaster struck when a fire, the cause of which remains unknown, razed the factory. Despite the devastation, several important pieces of heavy machinery and the brick exterior walls survived. With the office located elsewhere, the critical administrative functions remained intact. Quickly adapting to the situation, the company relied on pre-manufactured tools stored offsite to resume shipping.

Innovating Through the 1920-1930s

During the 1920s, Council Tool expanded its horizons beyond just making naval stores tools. This was due to transitioning from hand-forged methods to incorporating power hammers – this made shaping and welding tools faster and more efficient.

In this era, they started producing single-bit axes and innovated the double-edged bush axe. These early axes were crafted in two parts – the poll made from C1035 steel and the bit from high-carbon steel. The bits were hot-sheared, formed into a “U,” and forge-welded to the axe heads. The entire process was quite labor-intensive but marked the beginning of a new product line. Later in 1950, Council Tool switched to a more advanced technique forming one-piece axes.

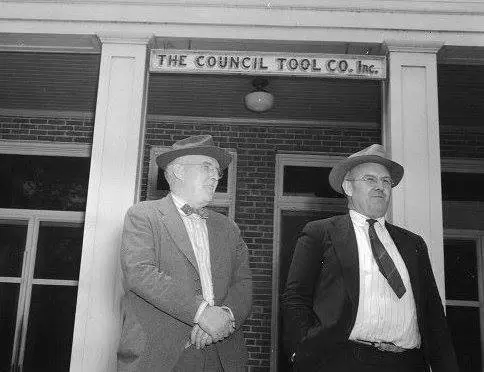

Sadly, the 20s also saw the passing of John Pickett Council in 1929. His son Clyde stepped up, carrying on the family legacy while being a state senator.

The 1930s also brought innovation in forestry tools. Council Tool developed hand seedling planting tools and the famous Council fire rake, a tool designed for firefighting that remains in use today. They also made fire swatters and ditch bank blades. Though the demand for some of these tools has dwindled with modern technology, their designs are still in use.

During WWII and the Post-War Years

When World War II began, Council Tool stepped up to support the military effort. The U.S. Defense Department urgently needed a specialized spanner wrench to set the explosive timer on artillery shells. The task was critical and demanded quick action. So, the company worked around the clock to design and produce these wrenches. Once ready, the tools were trucked to the Wilmington airport and then flown straight to Europe. Interestingly, these wrenches played a part in the Anzio Beach invasion in Italy. Another significant contribution during the war was making numerous forgings for the Wilmington shipyard.

Post-war, the rise of synthetic materials signaled the end of the naval stores industry, marking a pivotal shift for Council Tool. By around 1965, the company had phased out all related products. But this wasn’t the end – it was a new beginning. Council Tool diversified its product range, introducing nail pullers, digging bars, C-clamps, and post-hole diggers, among others. The evolution continued, with additions of pickhead fire axes, various sizes of hammers and sledges, wood-splitting mauls and wedges, and specialized forcible entry tools.

Modern Days

In early 1969, a fire struck again, severely damaging the manufacturing facilities at Council Tool. Luckily, Jack Council, the fourth president, had built great relationships in the hardware business. Many of these competitors-turned-friends offered to step up and help by manufacturing and shipping products for him. Jack also made sure his workers were taken care of. Instead of losing their jobs, employees were put to work on clean-up and rebuilding efforts, ensuring they didn’t miss out on a paycheck.

Over the years, Council Tool has been a go-to for custom forgings. Initially, this included farm tools and bike cranks – they once shipped out 20,000 bike cranks a week! Today, the company still produces various custom items, including forcible entry tools.

In 2011, to celebrate the company’s 125th anniversary, they launched a premium line of axes—Velvicut. Starting with American patterns like the 4-pound Dayton felling axe and the 2-pound Hudson Bay, these axes became a hit. The Woodcraft line, featuring European patterns, joined the mix in 2017. New product finishes and the launch of specialized tools, like the Flying Fox Hatchet, have kept Council Tool at the cutting edge. Additionally, the U.S. Forestry Service’s request for an updated, longer-handled Pulaski axe in 2020 exemplifies the ongoing innovation.

Council Tool’s commitment to quality extends to crafting fire tools. In 2022, they branded this line as Council Fire, offering municipal and wildland fire tools, along with a growing array of forcible entry tools. Feedback from firefighters has been crucial in designing these life-saving tools.

Traditionally, Council Tool bought hickory tool handles from vendors, but in 2019, they restarted in-house handle manufacturing. Waccamaw Woodworks, run by Council Rix, now manages this aspect of the business, ensuring family involvement continues.

Conclusion

The legacy of Council Tool is a testament to the power of quality, innovation, and resilience. From its humble beginnings in a log building to its status as a leading tool manufacturer, the company’s commitment to excellence has never wavered. For outdoor enthusiasts and woodworkers, the story of Council Tool is a source of inspiration and a reminder of the enduring value of craftsmanship.